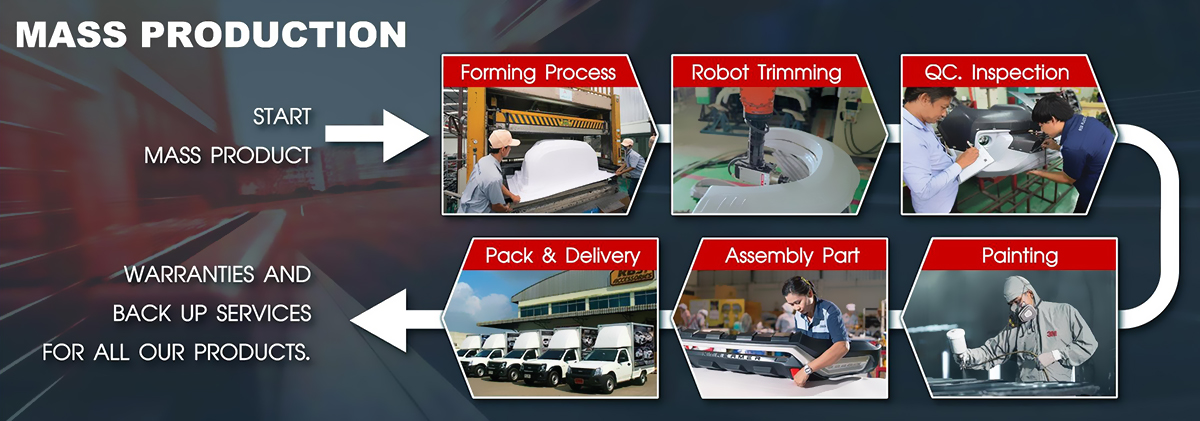

PRODUCTION PROCESS

We are mainly producing body parts for your favorite car.

Our car accessories are made from ABS Plastic and Acrylic which is extremely acceptable from car owners both local and overseas.

Especially the local market, it can distinguishable from many leading car manufacturers invest to locate the factory in Thailand. Therefore, we strive to develop our production process to reach the global standard.

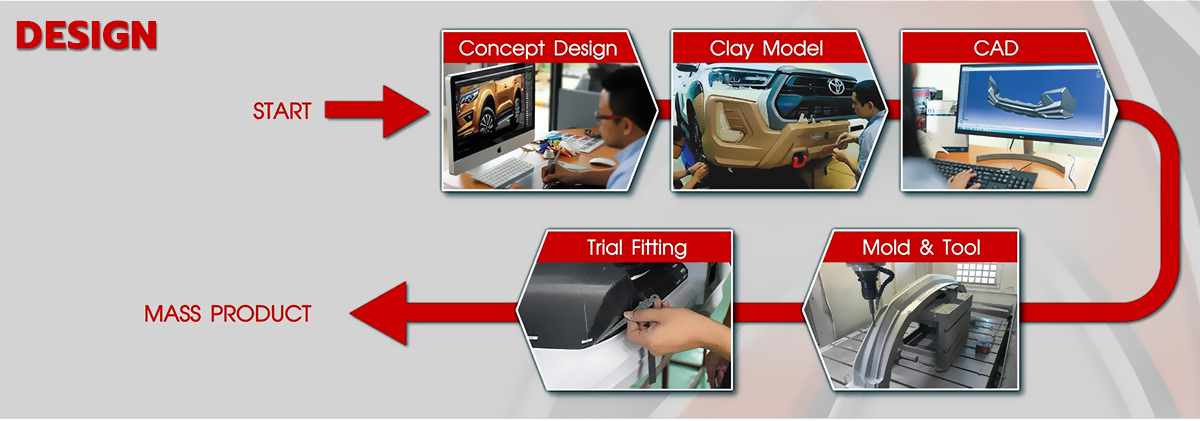

RSB Plastic always focuses on fashionable design and run away from copying. We have a great experienced creative team with modern tools. It is not only making a prototype but also controlling machines with the computer. In the competitive market, we must move forward otherwise we will be left behind.

PRODUCTION CAPACITY (SET / MONTH)

| Body Kits | 2,300 |

| Fender Flares | 2,700 |

| Body Clading | 1,100 |

| Bumper Guard | 2,000 |

| Spoiler | 4,600 |

| Bonnet Guard | 3,200 |

| Weather Shield | 11,000 |

| Cargo Tray | 2,700 |

Maximum capacity base on the year 2015-2020

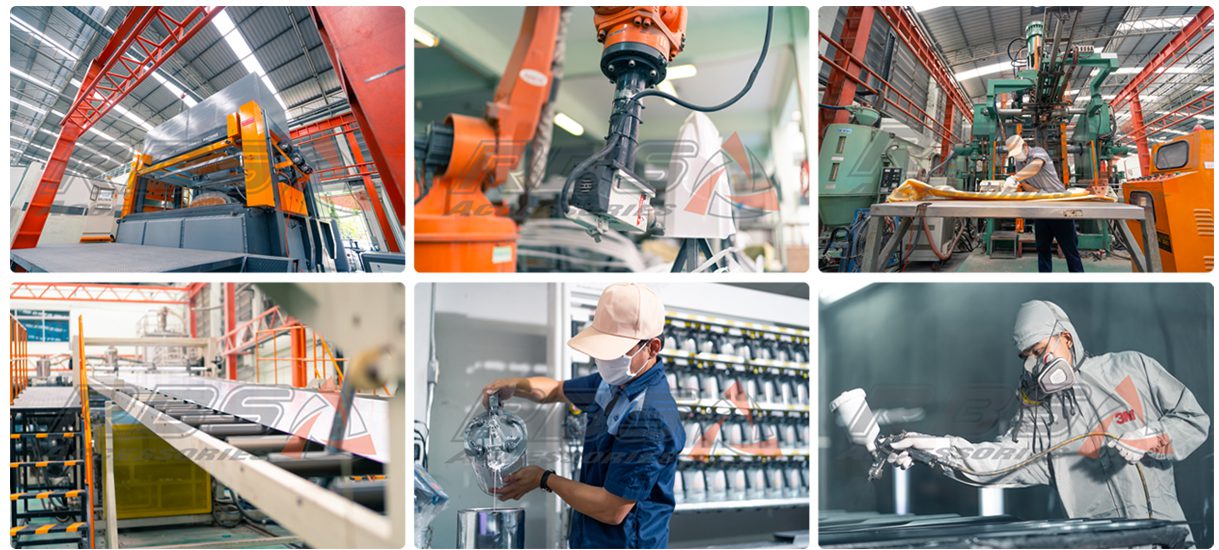

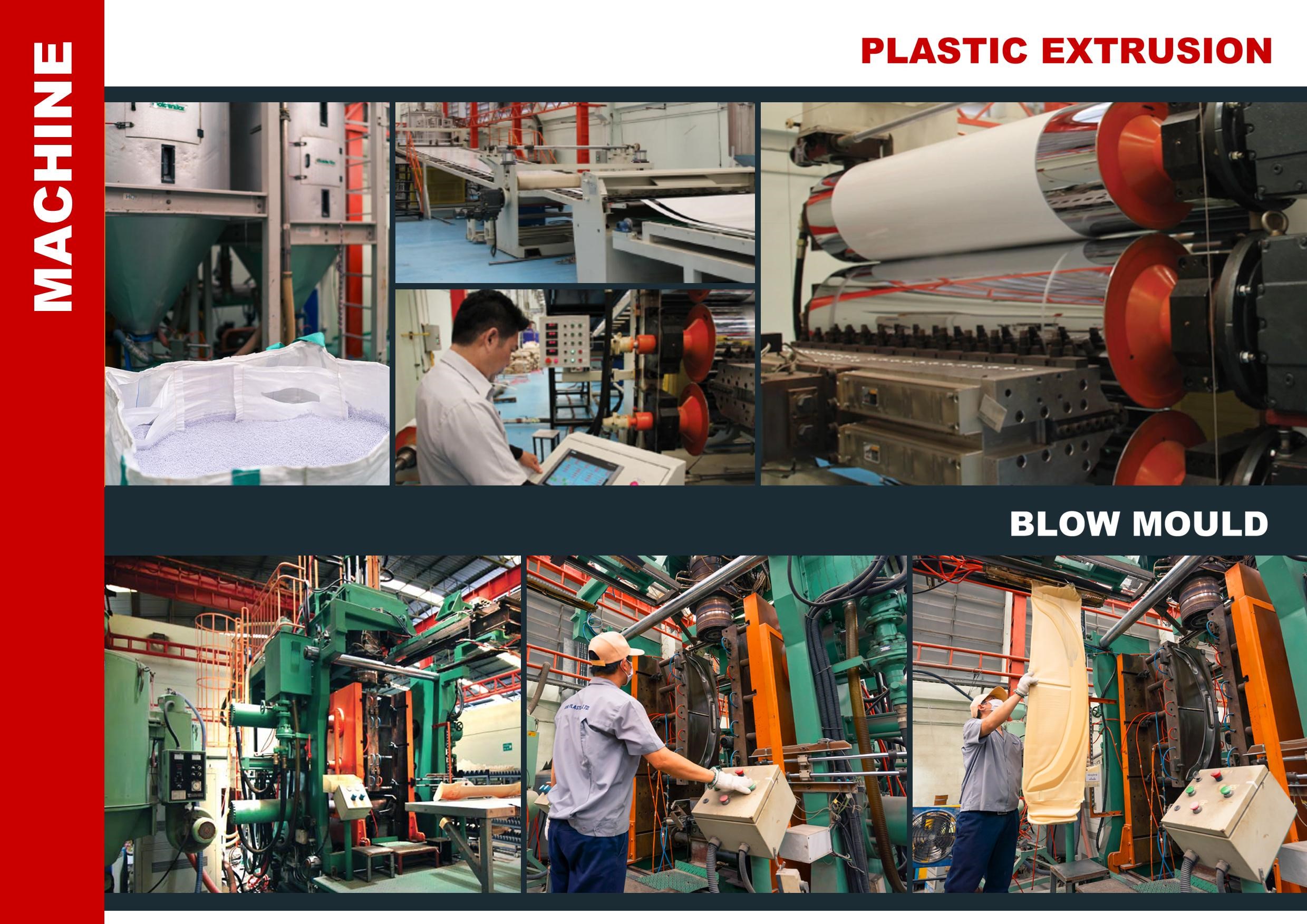

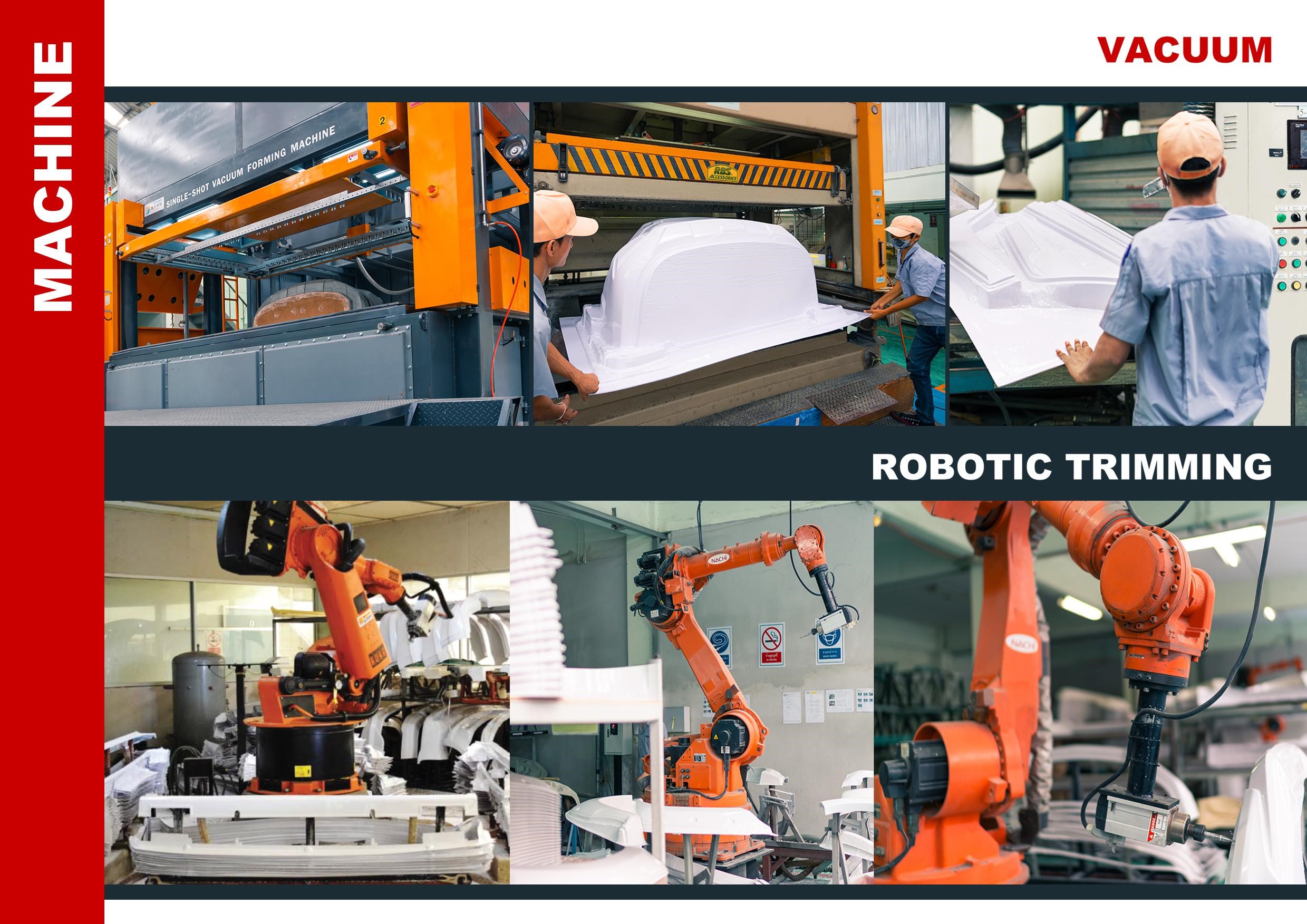

MACHINES & EQUIPMENT

| CNC Milling Machine | x 1 |

| Blow Mold Machine | x 1 |

| Vacuum Machine | x 15 |

| Robotic Trimming Machine | x 4 |

| Metal Stamping Machine | x 10 |

| ABS Plastic Extrusion Machine | x 1 |

| Spray Paint Booth | x 18 |